MD OF BIGHORN – With more companies looking to decrease their output of carbon emissions, Lafarge is hoping to do the same with two initiatives at its Exshaw plant.

The first initiative will look to use wind power to meet the energy demands of the plant. Under a Purchase Power Agreement with TransAlta, Lafarge will be supplied with 100-gigawatt hours per year of wind power for its cement plant.

There won’t be any wind turbines going up in Exshaw though, as this is a virtual Purchase Power Agreement (PPA), rather than a physical PPA.

“The agreement allows us to have access to the wind power that TransAlta is generating off its assets,” said Cailee Ellis, head of sustainability and environment of Lafarge Western Canada. “We anticipate that will cover between 40 and 50 per cent of the energy demands of the facility depending on production volumes.”

This is the first agreement of its kind for Lafarge in Alberta. The Exshaw plant was chosen because it constitutes 80 per cent of the energy demands in Lafarge’s Western Canada portfolio.

“We really saw it as an opportunity. Exshaw is our most significant consumer of our energy in Western Canada,” Ellis said.

If things go well through the agreement, there could be room for additional renewable energy use by the plant.

“This is our first foray into it but moving forward we will want to consider where there is additional capacity coming onto the grid because we do recognize that purchase power agreements are becoming very competitive,” Ellis said. “Access to renewables are becoming very competitive in Alberta where you traditionally have a very fossil fuel-based energy system.”

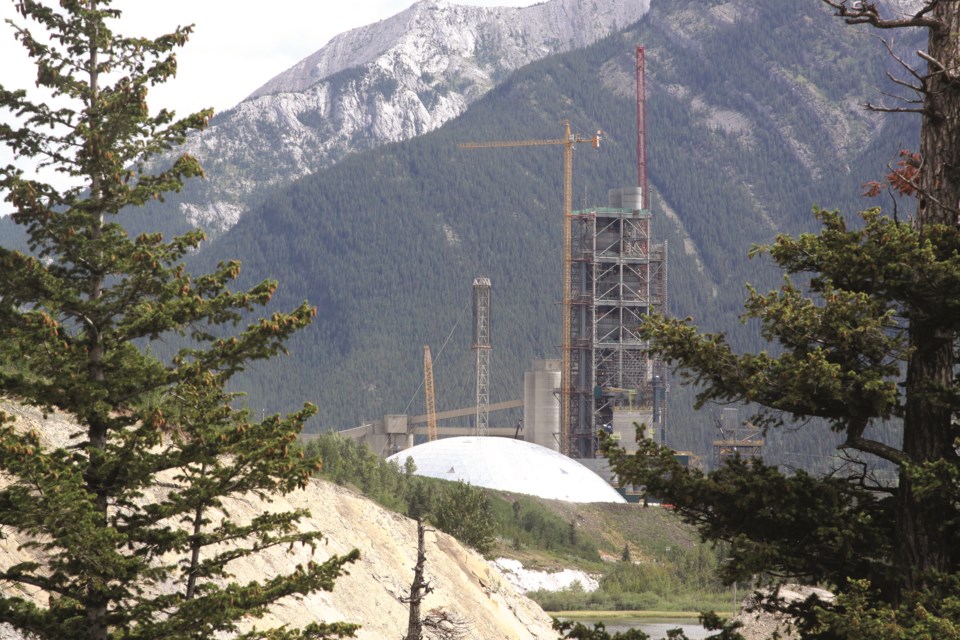

The second initiative will consist of burning low carbon fuels in Kiln 6 to reduce carbon emissions. Under the proposal, shredded wood, plastics and asphalt roof shingles will be burned, rather than using typical fossil fuels. Wood will make up 80 per cent of the material burned, while 20 per cent will be plastic and asphalts.

The material would be trucked in from the Lafarge Recycling Centre at the Spyhill Landfill, and ECCO Recycling in Calgary. The addition will result in 15 trucks a day delivering material to the plant, with a total increase to 25 trucks a day. To prevent traffic backing up on the highway, there will be on-site staging and trucks will be turned away if a backup occurs.

The Municipal Planning Commission of the MD of Bighorn did have concerns over the amount of dust control measures. Part of the agreement required minimizing the dust generated. Trucks would be sealed going into a sealed building, and then unloaded onto a sealed conveyor.

“We do see a lot of dust gets kicked up from increased road traffic and I understand that it is also going to be on pavement,” said MD of Bighorn councillor Joss Elford “Is there any way to mitigate kicking up off the road?”

Lafarge stated in the commission meeting that there should be little dust churned up by trucks, and that they were working to mitigate dust in the air from the processes of the plant itself.

“The dust coming off the road, we have our sweepers and water trucks and we can just increase the frequency to control the dust from those road sources,” said Nick Veriotes, manager of environment and public affairs with Lafarge. “That would be for three of the four seasons. In the winter, things freeze and any water there would freeze but we are looking at foaming agents that we can use in the winter or other materials to apply to reduce any dust.”

The PPA with TransAlta will provide electricity for the project.

“Bringing in low carbon fuels is one of the most important pieces in terms of using that in place of traditional fossil fuels that are used to heat kilns,” Ellis said. “We also use energy at the facility, so how can we also decarbonize the energy that we are purchasing at the market to bring it into the facility.”

With the power consumption of the plant, Lafarge is hoping that both initiatives will go a long way to reducing the company’s carbon emissions in the province.

“When we look at our energy portfolio and recognize how significant Exshaw’s consumption of that is, it was our primary focus,” Ellis said. “All things considered, when we look at broad energy management, it is about energy efficiency.”